Strict quality control system and perfect after-sales service system are always our top concern which can guarantee and track the quality of our products from raw materials procurement, production processes, finish products as well as after-sales service.

Test:SGS or Third- party test

Delivery: 5-7days after deposit

Welded steel pipe's surface always the balck .And also it is made of 10, 20, 30, 35, 45 high quality carbon bonded steel 16Mn, 5MnV and other low alloy structural steel or 40Cr, 30CrMnSi, 45Mn2, 40MnB and other alloy steel hot rolled or cold rolled. 10, 20 and other low carbon steel made of seamless pipe is mainly used for fluid conveying pipeline. 45, 40Cr and other medium carbon steel made of seamless pipe to manufacture machine parts, such as cars, tractors, force parts. Generally used carbon steel pipe to ensure the strength and flattening test. Hot rolled steel pipes are delivered in hot rolled or heat treated state; Cold rolling is delivered in heat treatment condition.

|

Conventional Parameters |

|

|

OD |

for hot rolled ,over 32mm ; if cold rolled,can up to 6mm |

|

Length |

5.8-12m or according to your needs |

|

Thickness |

for hot rolled :2.5-75 mm;for cold rolled:Min 0.25mm |

|

Material |

Q235A,Q235B,1010,1020,Q345(16Mn)L245(B),L290(X42),L320(X46),L360(X52)、L390(X56)、L415(X60)、L450(X65),L485(X70),L555(X80),L290NB/MB(X42N/M),L360NB/MB(X52N/M),L390NB/MB(X56N/M),L415NB/MB(X60N/M)、L450MB(X65)、L485MB(X70)、L555MB(X80) |

|

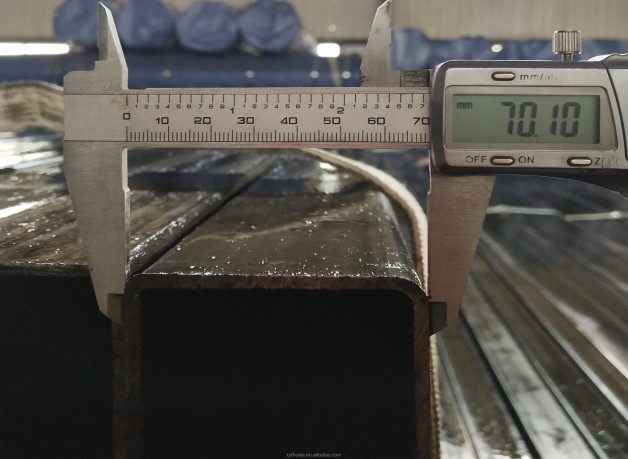

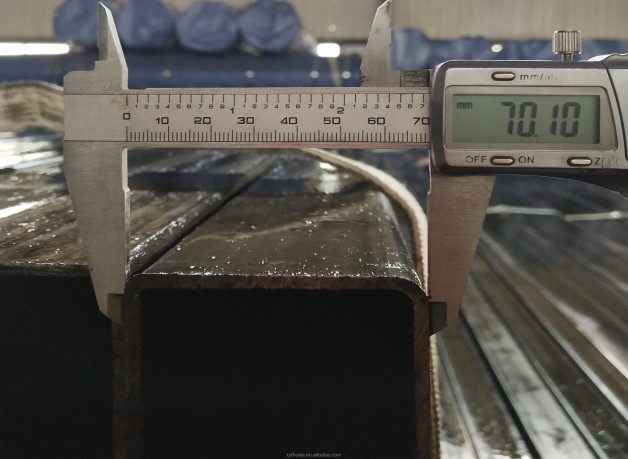

Tolerance |

±0.5 |

|

Processing Service |

Welding, Punching, Cutting, Bending, Decoiling |

|

Payment term |

T/T (30% Deposit),L/C or negotiate with big amount |

|

MOQ |

5Tons |

|

Packing |

Standard Sea-worthy Packing |

|

Standard |

AISI,ASTM,DIN,JIS,GB ,JIS,SUS,EN,etc |

A.In the process of forming, the steel plate has uniform deformation, small residual stress and no scratch on the surface. The processed spiral steel pipe has greater flexibility in diameter and wall thickness size and specification range, especially in the production of high steel grade thick wall pipe, especially in small and medium caliber thick wall pipe has incomparable advantages in other processes, can meet the user's more requirements in spiral steel pipe specifications.

B. Adopting advanced double-sided submerged arc welding technology, welding can be realized in the best position, and it is not easy to have defects such as wrong side, welding deviation and incomplete welding, and it is easy to control the welding quality.

C. 100% quality inspection of steel pipe is carried out, so that the whole process of steel pipe production is effectively detected and monitored, and the product quality is effectively guaranteed.

D. All the equipment of the whole production line has the function of networking with the computer data acquisition system to realize real-time data transmission, and the technical parameters in the production process are checked by the central control room.

Welded steel pipe is mainly used in tap water engineering, petrochemical industry, chemical industry, electric power industry, agricultural irrigation, urban construction.

For liquid transportation: water supply, drainage. For gas transportation: gas, steam, liquefied petroleum gas. For structural use: for piling pipes, Bridges; Pipe for wharf, road, building structure, etc.