Strict quality control system and perfect after-sales service system are always our top concern which can guarantee and track the quality of our products from raw materials procurement, production processes, finish products as well as after-sales service.

Test:SGS or Third- party test

Delivery: 5-7days after deposit

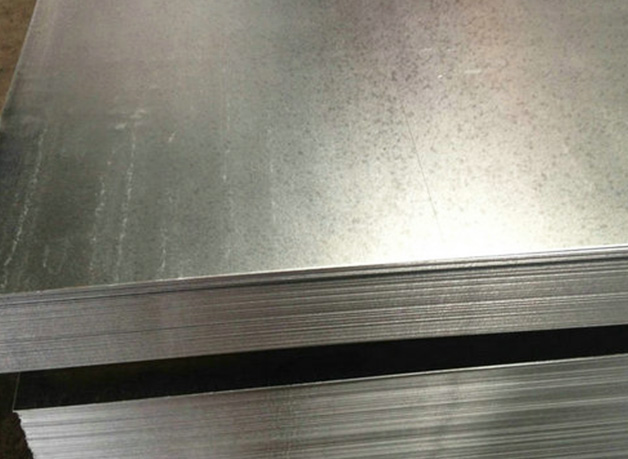

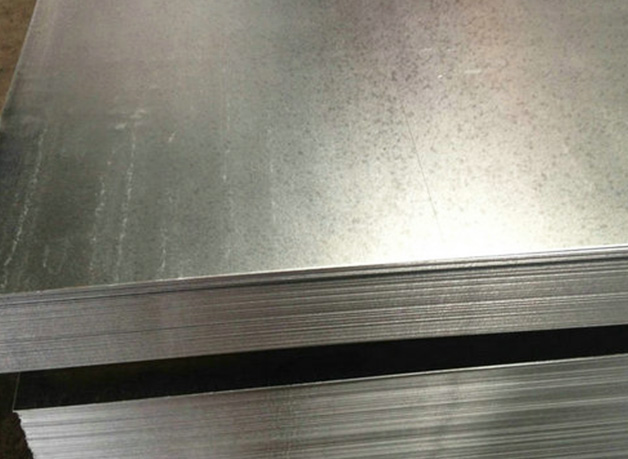

Galvanized plate, dipping a sheet of steel into a molten zinc bath so that it adheres to a sheet of zinc on its surface. The main use of continuous galvanizing process production, that is, into a roll of steel plate continuous dip in the melting of zinc plating tank made of galvanized steel plate; Alloyed galvanized steel sheet. This steel plate is also made by hot dip, but immediately after the trough, it is heated to about 500℃, so that it generates an alloy film of zinc and iron. This galvanized coil has good coating adhesion and weldability.

| The differences between hot dip galvanized and electrogalvanized. | |

| Theory | Hot dip galvanizing occurs when steel is dipped in liquid zinc. |

| Electrogalvanizing a galvanized layer is attached to the surface of the steel by an electrochemical method. | |

| Surface | Hot dip galvanized surface is rough, coating range 30-60㎛. |

| Electrogalvanizing has a smooth surface with a coating range of 5-30㎛. | |

| Usage | Hot dip galvanized is mostly used for outdoor facilities. |

| Electrogalvanizing is used in panel and other indoor steel. | |

|

Conventional Parameters |

|

|

Width |

Plate: 600-2250mm Strip:24-600mm |

|

Length |

1-12m |

|

Thickness |

0.3-250 mm |

|

Grade |

SECC,SECD,SECE,Zn100-PT,Zn200-SC,Zn275-JY,SGCC,SGCD1,SGCD2,SGCD3,St01Z,St02Z,St03Z,St04Z, St05Z,etc. |

|

Material |

Q195/Q215A/Q215B/Q235A/Q235B/Q295A/Q295B/Q345A/Q345B,st12,st13,st14,st15,st14-Tetc. |

|

Zinc layer code |

Z40,Z80,Z100,180,200,275,350,450,600etc. |

|

Payment term |

T/T (30% Deposit) |

|

MOQ |

5Tons |

|

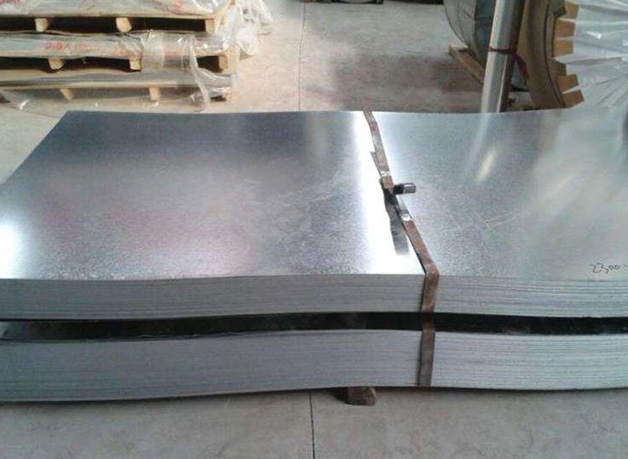

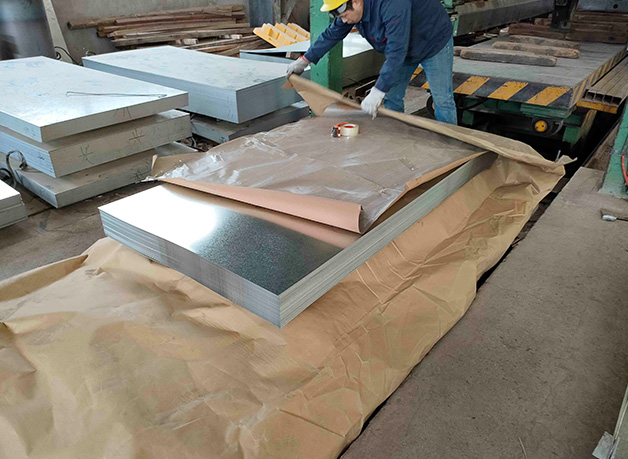

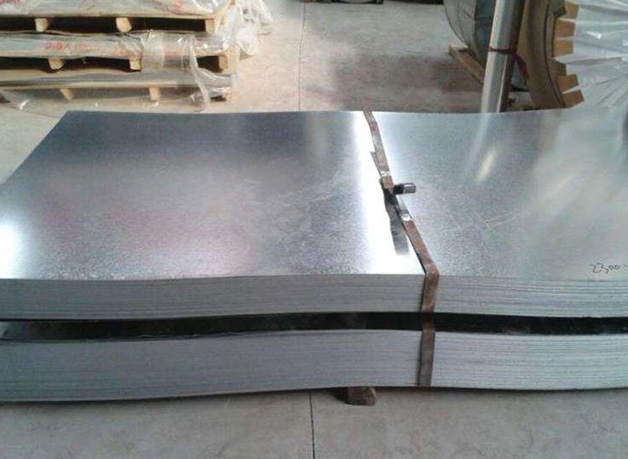

Packing |

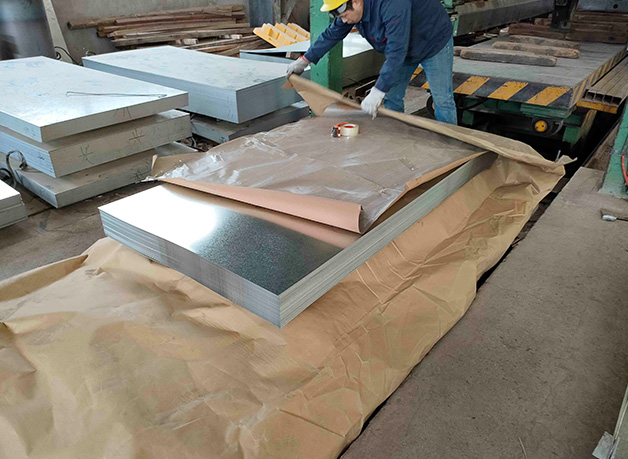

Standard Sea-worthy Packing |

|

Standard |

EN,GB,ASTM,JIS,DIN,etc. |

|

Zinc layer definition |

|

|

N/NS |

Zinc layer in the normal solidification process, zinc grains grow freely formed with obvious spangle morphology of the coating. |

|

M/MS |

During the solidification process of zinc layer, zinc grains are artificially restricted to form as fine spangle coating as possible. |

|

F/FS |

Spangle can not be seen with the naked eye on the board, known as no spangle, also known as zero spangle, which is completed by controlling the chemical composition of zinc liquefaction. When hot-dip galvanizing, only add a certain amount of aluminum to zinc solution, without adding lead, antimony, tin, can produce zinc-free flower products. This process does not increase equipment, does not increase production costs, can obtain uniform surface appearance, so this process has been widely promoted in the world. |

Spangle only has ornamental value, no practical value, on the contrary, zinc flower is not good in corrosion resistance, surface coating will appear convex and concave level.

Color coated roll has light weight, beautiful and good corrosion resistance, and can be directly processed, the color is generally divided into gray, blue, brick red, mainly used in advertising, construction, household appliances, electrical appliances, furniture industry and transportation industry.

The coating used for color coating rolls according to the use of different environment to choose the appropriate resin, such as polyester silicon modified polyester, PVC plastisol, poly vinylidene chloride and so on. Users can choose according to usage.