Strict quality control system and perfect after-sales service system are always our top concern which can guarantee and track the quality of our products from raw materials procurement, production processes, finish products as well as after-sales service.

Test:SGS or Third- party test

Delivery: 5-7days after deposit

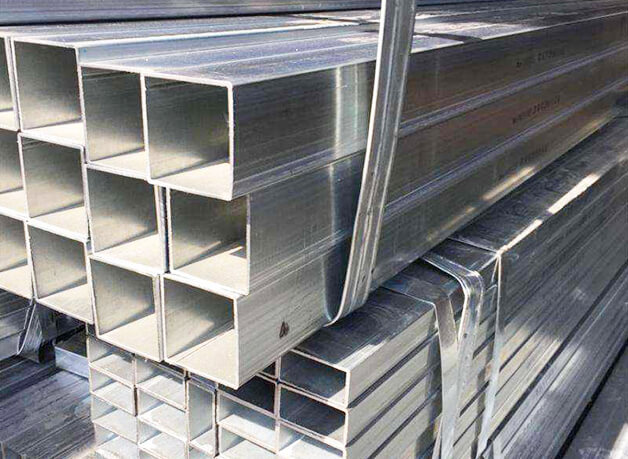

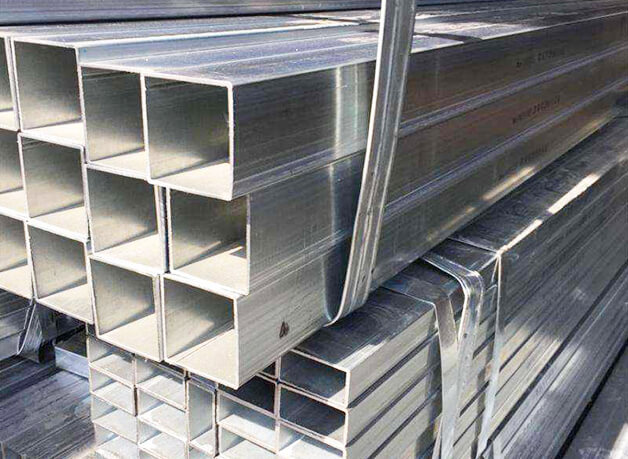

Hot dip galvanized tube is to make molten metal and iron matrix reaction and produce alloy layer, so that the matrix and coating of the combination of the two. Hot dip galvanizing is the first steel pipe pickling, in order to remove iron oxide on the surface of the steel pipe, pickling, through ammonium chloride or zinc chloride aqueous solution or ammonium chloride and zinc chloride mixed aqueous solution tank for cleaning, and then into the hot dip plating tank. Hot dip galvanizing has the advantages of uniform coating, strong adhesion and long service life. Complex physical and chemical reactions occur between hot dip galvanized steel tube and molten plating solution to form a tightly structured zinc-ferroalloy layer with corrosion resistance. The alloy layer is integrated with pure zinc layer and steel tube matrix, so its corrosion resistance is strong.

|

Conventional Parameters |

|

|

Width |

500-3000 mm |

|

Nominal Wall Thickness |

2.0、2.5、2.8、3.2、3.5、3.8、4.0、4.5mm |

|

Grade |

Zn100-PT,Zn200-SC,Zn275-JY,SGCC,SGCD1,SGCD2,SGCD3,St01Z,St02Z,St03Z,St04Z,St05Z,etc. |

|

Type |

Round, Square, Rectangular |

|

Material |

Q195/Q215A/Q215B/Q235A/Q235B/Q295A/Q295B/Q345A/Q345B,st12,st13,st14,st15,st14-T,etc. |

|

Zinc layer code |

Z40,Z80,Z100,180,200,275,350,450,600etc. |

|

Standard |

EN,GB,ASTM,JIS,DIN,etc. |

|

Payment term |

T/T (30% Deposit) |

|

MOQ |

5Tons |

|

Packing |

Standard Sea-worthy Packing |

|

Standard |

AISI,ASTM,DIN,JIS,GB ,JIS,SUS,EN,etc |

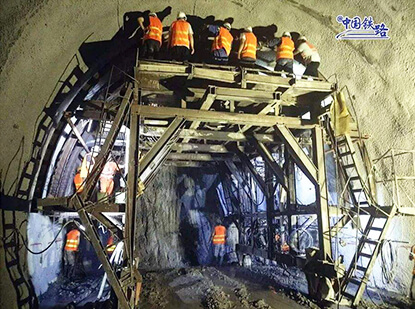

Hot dip galvanized steel pipe is widely used in construction, machinery, coal mine, chemical industry, electric power, railway vehicles, automobile industry, highway, bridge, container, sports facilities, agricultural machinery, petroleum machinery, prospecting machinery, greenhouse construction and other manufacturing industries.

Welded steel tubes with hot dip or electrogalvanizing coating. Galvanizing can increase the corrosion resistance of steel pipe and prolong its service life. Galvanized pipe USES is very wide, in addition to a general low pressure fluid such as water, gas, oil line pipe, also used as oil industry, especially the ocean oil field oil well pipe, oil pipe, chemical coking equipment of oil heater, the condensing, exchange of coal distillation wash oil cooler for tube, and trestle pile, mining tunnel supporting frame tube, etc.