Strict quality control system and perfect after-sales service system are always our top concern which can guarantee and track the quality of our products from raw materials procurement, production processes, finish products as well as after-sales service.

Test:SGS or Third- party test

Delivery: 5-7days after deposit

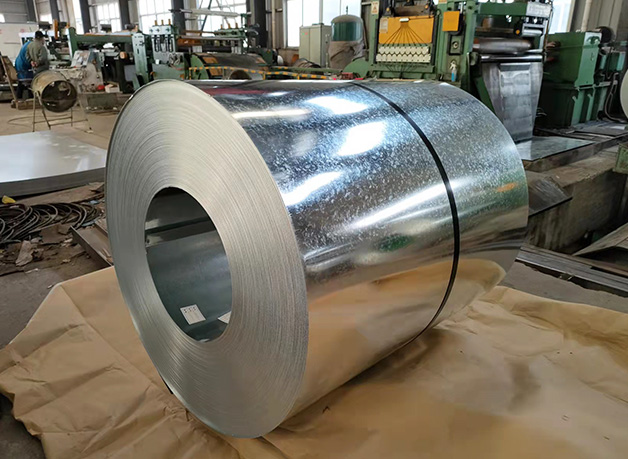

Electrogalvanizing,it is also known as cold galvanizing in the industry, which is a process of forming uniform, dense and well-combined metal or alloy deposition layer on the surface of the workpiece by electrolysis.

Compared with other metals, zinc is relatively cheap and easy to coat a metal, a low value corrosion resistance electroplating, is widely used to protect steel parts, especially against atmospheric corrosion, and used for decoration.

| The differences between hot dip galvanized and electrogalvanized. | |

| Theory | Hot dip galvanizing occurs when steel is dipped in liquid zinc. |

| Electrogalvanizing a galvanized layer is attached to the surface of the steel by an electrochemical method. | |

| Surface | Hot dip galvanized surface is rough, coating range 30-60㎛. |

| Electrogalvanizing has a smooth surface with a coating range of 5-30㎛. | |

| Usage | Hot dip galvanized is mostly used for outdoor facilities. |

| Electrogalvanizing is used in panel and other indoor steel. | |

|

Conventional Parameters |

|

|

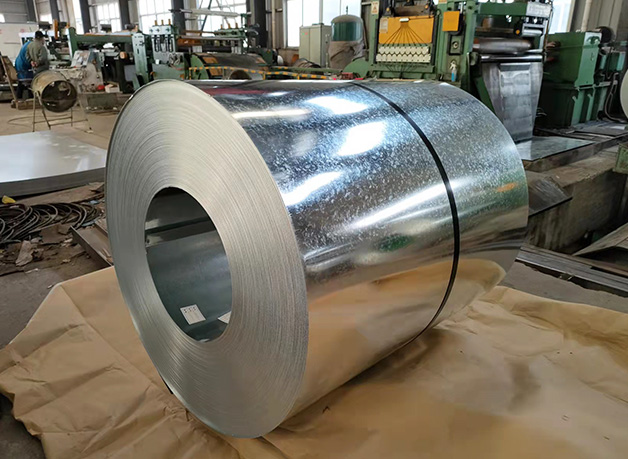

Width |

500-3000 mm |

|

Thickness |

0.2-4 mm |

|

Grade |

SECC,SECD,SECE,Zn100-PT,Zn200-SC,Zn275-JY,SGCC,SGCD1,SGCD2,SGCD3,St01Z,St02Z,St03Z,St04Z, St05Z,etc. |

|

Material |

Q195/Q215A/Q215B/Q235A/Q235B/Q295A/Q295B/Q345A/Q345B,st12,st13,st14,st15,st14-Tetc. |

|

Zinc layer code |

Z40,Z80,Z100,180,200,275,350,450,600etc. |

|

Payment term |

T/T (30% Deposit) |

|

MOQ |

5Tons |

|

Packing |

Standard Sea-worthy Packing |

|

Standard |

EN,GB,ASTM,JIS,DIN,etc. |

|

The specialty of electrogalvanizing |

|

|

1 |

Good corrosion resistance, fine and uniform bonding, not easy to be corrosive gas or liquid into the interior. |

|

2 |

Because the zinc layer is relatively pure, it is not easy to be corroded in acid or alkali environment. Long time effective protection of steel body. |

|

3 |

Chromic acid passivation after forming a variety of colors to use, can be selected according to the customer's favorite, galvanized beautiful and generous, with decorative. |

|

4 |

Zinc coating has good ductility, in all kinds of bending, handling impact will not easily fall off. |