Strict quality control system and perfect after-sales service system are always our top concern which can guarantee and track the quality of our products from raw materials procurement, production processes, finish products as well as after-sales service.

Test:SGS or Third- party test

Delivery: 5-7days after deposit

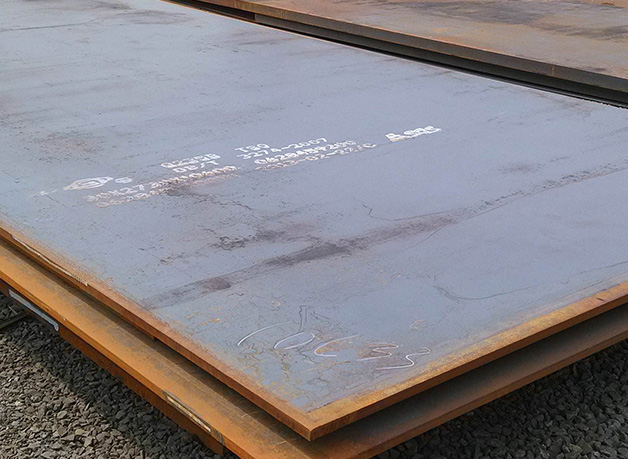

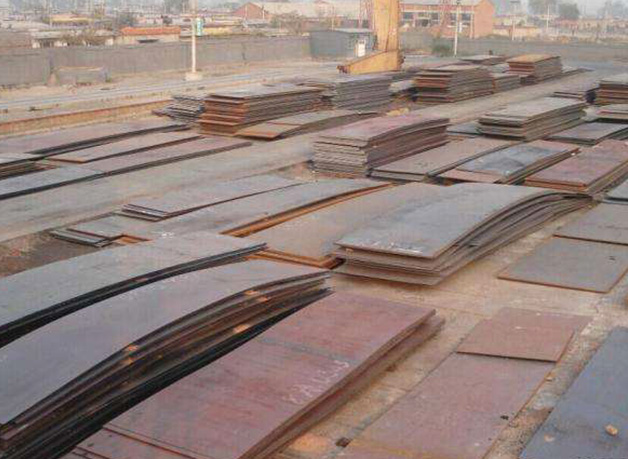

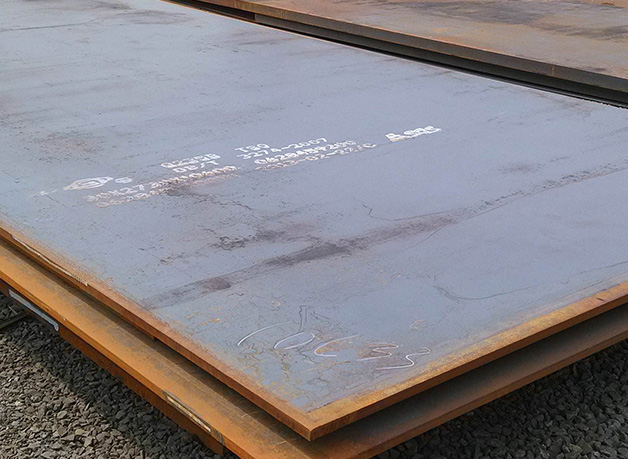

Weather resistant structural steel is atmospheric corrosion resistant steel, belongs to low alloy high strength structural steel, according to its main characteristics are divided into high weather resistant structural steel and welding structure with weather resistant steel.

|

Conventional Parameters |

|

|

Width |

Plate: 600-2250mm |

|

Length |

1-12m |

|

Thickness |

0.3-250 mm |

|

Material |

Q235NH,Q355NH,Q355GNH,09CuPCrNi-A,ASTM A588,S355J0W, S355J2W, S355K2W, S355J0WP ,S355J2WP,SMA400AW/BW/CW, SAM490AW/BW/CW/, SAM570W/P, etc. |

|

Processing Service |

Welding, Punching, Cutting, Bending, |

|

Payment term |

T/T (30% Deposit) |

|

MOQ |

5Tons |

|

Packing |

Standard Sea-worthy Packing |

|

Standard |

AISI,ASTM,DIN,JIS,GB ,JIS,SUS,EN,etc

|

|

High strength weathering steel |

Weathering steel for welded structures |

|

High weather resistant steel is a small amount of copper in steels, phosphorus, chromium, nickel element, in the protective layer is formed on the metal surface of the collective, to improve the performance of atmospheric corrosion resistant steel, you can also add a small amount of molybdenum, niobium, vanadium, titanium, zirconium, such as elements, with fine grains, increase mechanical properties of the steel, improving steel strong toughness, reduce the brittle transition temperature, So that it has better brittle breaking resistance. |

The elements added to the steel grade, except for phosphorus, are basically the same as high weatherability structural steel, and its role is also the same, and improve welding performance. |

The use of high weatherability structural steel because of its atmospheric corrosion resistance is better than welding structure weatherability steel, mainly used in vehicles, containers, buildings, towers and other structures with the bolted, riveted and welded structural parts. When welding structural parts, the thickness of steel should not be greater than 16mm. The welding performance of weathering steel for welding structure is better than that of high weathering structural steel, and it is mainly used for welding structural parts of Bridges, buildings and other structures.