Strict quality control system and perfect after-sales service system are always our top concern which can guarantee and track the quality of our products from raw materials procurement, production processes, finish products as well as after-sales service.

Test:SGS or Third- party test

Delivery: 5-7days after deposit

20CR alloy structural steel: compared with 15Cr steel, it has higher strength and hardenability, and it still has grain growth tendency when carburizing.

40CR alloy structural steel: tensile strength, yield strength and hardenability are higher than 40 steel, but the weldability is limited, there is a tendency to form cracks. It has the best comprehensive mechanical properties.

|

Chemical Composition |

||||

|

Grade |

C |

Mn |

Si |

Cr |

|

20Cr/5120 |

0.18-0.24 |

0.50-0.80 |

0.17-0.37 |

0.70-1.00 |

|

40Cr/5140 |

0.37-0.44 |

0.50-0.80 |

0.17-0.37 |

0.80-1.10 |

|

Permissible residual content |

||||

|

Grade |

S |

P |

Ni |

Cu |

|

20Cr/5120 |

≤0.035 |

≤0.035 |

≤0.030 |

≤0.030 |

|

40Cr/5140 |

≤0.035 |

≤0.035 |

≤0.030 |

≤0.030 |

|

Mechanical Property |

||||||

|

Grade |

Tensile |

Yield |

Elongation |

Reduction |

Hardness |

Akv |

|

20Cr/5120 |

≥835 |

≥540 |

≥10 |

≥40 |

≤179HB |

≥47 |

|

40Cr/5140 |

≥980(100) |

≥785(80) |

≥9 |

≥45 |

≤207HB |

≥47 |

|

Sample size: 20Cr/5120:sample blank size is 15mm |

||||||

|

Conventional Parameters |

|

|

OD |

20-500mm |

|

Length |

5.8-12m |

|

Thickness |

0.5-40 mm |

|

Alloy or not |

Alloy |

|

Tolerance |

±0.5% |

|

Payment term |

T/T (30% Deposit) |

|

MOQ |

5Tons |

|

Packing |

Standard Sea-worthy Packing |

|

Standard |

AISI,ASTM,DIN,JIS,GB ,JIS,SUS,EN,etc |

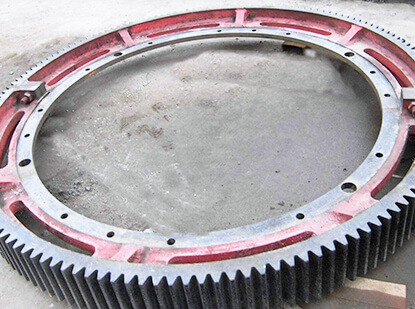

Application example :20CR alloy structural steel is mostly used to manufacture carburized parts (oil quenching) with high core strength requirements, surface wear resistance, section below 30mm or complex shape and small load, such as machine tool transmission gear, gear shaft, CAM, worm, piston pin, claw clutch, etc.; For parts with small deformation and high wear resistance under heat treatment, high frequency surface quenching should be carried out after carburizing, such as gears, shafts and spline shafts with modulus less than 3. This steel can also be used in the condition of quenching and tempering, used to manufacture parts with high working speed and moderate impact load, this steel can also be used for low carbon martensitic hardening steel, further increasing the yield strength and tensile strength of steel (about 1.5 ~ 1.7 times).

Chemical composition editing