Strict quality control system and perfect after-sales service system are always our top concern which can guarantee and track the quality of our products from raw materials procurement, production processes, finish products as well as after-sales service.

Test:SGS or Third- party test

Delivery: 5-7days after deposit

Chromium-molybdenum steel, also known as medium temperature hydrogen resistant steel, is an alloy of chromium (Cr), molybdenum (Mo), iron (Fe), carbon (C). Because of its special high quality performance, it is often used to manufacture some high temperature and high pressure resistant valves and pressure vessels, such as chromium-molybdenum steel safety valve, chromium-molybdenum steel gate valve, screwdriver head, bicycle and so on.

|

Chemical Composition |

||||||||

|

Grade |

C |

Mn |

Si |

Cr |

Mo |

Ni |

S |

Cu |

|

15CrMo |

0.12~0.18 |

0.40~0.70 |

0.17~0.37 |

0.80~1.10 |

0.40~0.55 |

≤0.30 |

≤0.035 |

≤0.035 |

|

20CrMo |

0.17~0.23 |

0.40~0.70 |

0.17~0.37 |

0.80~1.10 |

0.15~0.25 |

≤0.30 |

≤0.035 |

≤0.035 |

|

30CrMo |

0.26~0.34 |

0.40~0.70 |

0.17~0.37 |

0.80~1.10 |

0.15~0.25 |

≤0.30 |

≤0.035 |

≤0.035 |

|

35CrMo |

0.32~0.40 |

0.40~0.70 |

0.17~0.37 |

0.80~1.10 |

0.15~0.25 |

≤0.30 |

≤0.035 |

≤0.035 |

|

42CrMo |

0.38~0.45 |

0.50-0.80 |

0.17~0.37 |

0.90~1.20 |

0.15~0.25 |

≤0.30 |

≤0.035 |

≤0.035 |

|

Mechanical Property |

||||

|

Grade |

Tensile |

Yield |

Elongation |

Reduction |

|

15CrMo |

440~640 |

295 |

≥22 |

≥50 |

|

20CrMo |

≥885(90) |

≥685(70) |

≥12 |

≥50 |

|

30CrMo |

≥930 |

≥785 |

≥12 |

≥50 |

|

35CrMo |

≥985(100) |

≥835(85) |

≥12 |

≥45 |

|

42CrMo |

≥1080(110) |

≥930(95) |

≥12 |

≥45 |

|

Conventional Parameters |

|

|

OD |

20-500mm |

|

Length |

5.8-12m |

|

Thickness |

0.5-40 mm |

|

Alloy or not |

Alloy |

|

Tolerance |

±0.5% |

|

Payment term |

T/T (30% Deposit) |

|

MOQ |

5Tons |

|

Packing |

Standard Sea-worthy Packing |

|

Standard |

AISI,ASTM,DIN,JIS,GB ,JIS,SUS,EN,etc |

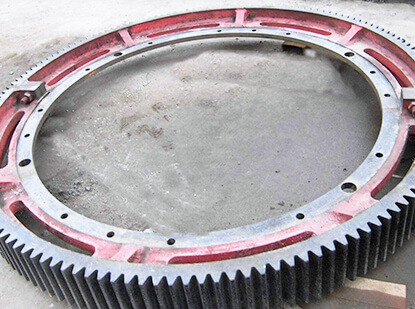

Used for important structural parts that work under high loads, such as transmission parts of vehicles and engines; The rotor, spindle and heavy load drive shaft of the turbine generator; Perforators for petroleum industry; Temperature on boiler < Temperature for fasteners and chemical equipment at 480°C < Thick wall high pressure conduit operating in 500°C and non-corrosive media; It can replace 40CrNi for large section parts, used for forgings requiring higher strength or larger section than 35CrMo steel, such as locomotive traction with large gear, turbocharger drive gear, rear shaft, engine cylinder, 1200-2000 meters deep oil drilling pipe joints and fishing tools. It can substitute quenched and tempered steel with higher nickel content